Our portfolio covers services and equipment developed and manufactured by REK Innovation in Germany.

The core of our technological concept is a versatile process chamber, which can be adapted and combined as well for common applications as vacuum reflow soldering as for novel processes that we even have not yet thought of. The brain of our universal process chamber is implemented in a revolutionary next-generation automation platform. With a forward-looking software architecture, REK Innovation enters together with its technology partner the era of Internet of Things (IoT) and Smart Manufacturing.

With our new approach, we are able to change and control a wide variety of process parameters in a defined manner and reach unlimited functionality. Regardless of whether you are looking for a solution for 24/7 production with focus on highest throughput or you need to operate in an engineering mode for tuning parameters in real-time. Comprehensive IoT connectivity enables short-term support worldwide reducing costs to a minimum. Certified IT security standards are fully integrated and provide maximum protection.

The SC series

The smart processing core

REK Innovation proudly presents the next generation smart chamber system. The base of the SC series is a versatile single chamber processing core for various applications. It combines the flexibility and capability of a R&D platform with the design for high performance and reliability of 24/7 production equipment. In this platform, we have implemented decades of experience in packaging technology.

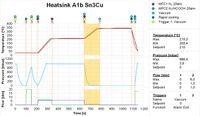

The SC series has a working space of 400x350x70mm. Temperature can be precisely controlled up to 1000°C and pressure down to high vacuum. The SC series is ready for processing with inert and explosive gases and vapours as needed for formic acid assisted flux less reflow soldering. With our innovative, high precision, and self-calibrating gas controlling module, you can configure by yourself various gas types up to your needs. The temperature of process chamber and your product is controllable precisely during every process stage. The heating and cooling method can be easily configured. Thus, the chamber offers as well contact as contactless thermal processing, which enables a high level of customization for all kinds of loads like power electronics on DBC or AMB substrates. In this way, heating and cooling are independent on the chamber pressure and gas composition. And extraordinary fast! Optional features are available in a huge variety enhancing your capabilities in process design, control and monitoring.

We offer all kinds of services you need to run your process successfully. We support your process development and optimization in a variety of frontend and backend processes. Our systems installed at our headquarters in Munich are available to demonstrate or verify your process for various applications as device packaging, soldering of large area substrates, die attach, etc. We support you to keep your processing equipment running and well maintained. Our services comprise trainings, maintenance, repair, spare part logistics, updates and upgrades of SC series systems as well as of equipment of other suppliers. Our services are the key to optimize your equipment for your process and keep it running.

Questions about our products and services?

.jpg/picture-200?_=19049f0cbe0)